In the morning we headed up to the small town of Moléson to watch cheese being made traditionally in an alpine hut. When we arrived, the curds were being heated in a huge cauldron over a wood fire. After they reached the correct consistency and temperature, the man making the cheese reached in with cheesecloth of some sort to lift out the curds and put them into the cheese mould. We decided he must have very strong arms to lift that amount of curd out of the cauldron – it looked really heavy but he did use small electric crane to aid him along! After he put them in the mould, he put a weight on them to press the liquid out.

We learned that his cheese is an "alpage" cheese which means that all of the milk comes from one herd of cows. If he used cheese from his neighbour's herd, it would be called “montagne” (mountain). We then watched a video on them making the cheese in the high alps during the summer. At the end, Anoop sampled some of their cheeses and picked up a “petit lutin”.

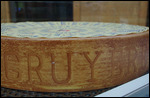

After lunch we drove over to Gruyères to go to the factory; the entrance fee included a fairly large sample of 3 different ages of gruyere which were sealed for sampling then or later. The audio guided tour was from the cow’s perspective and our guide, Cherry (named so because she was born in the cherry season), led us through the cheese making process with lots of useful information. On the tour, we could smell the different flowers and herbs that the cows would eat and that you can smell or taste in the cheese. We continued listening while we waited for the cheese curds to reach the correct consistency in the vats.

The men kept checking it by scooping some out and squeezing it in their hands; once it reached the right consistency, they started filling the moulds with the mixture. The curds and liquid come pouring out of tubes until the huge vat is empty. Then, once some of the liquid has drained out, they put on the date and batch number to identify the cheese and a lid to continue pressing it. The factory makes 12 rounds of gruyere per vat and up to 48 rounds per day. The rounds are then aged on untreated, spruce planks for various times.

Afterwards we headed up to the town of Gruyères to wander around. We saw an old stone structure in the middle of town that had different sized holes in it that were used for measuring grain in the old days. We also stopped off at a small shop that had a fabulous exhibit of an Italian artist, Massimo Cruciani. He does painting on glass and the shop had done a great job with the displays; the light shining on the paintings was beautiful. We particularly liked the pictures of poppies since they stood out so well. We walked around the outside of the castle, but our guidebook had said it wasn’t particularly interesting inside so we gave it a miss.

Once back in camp, Anoop decided to head up to le Moléson (where we had been earlier this morning at the Alpine hut) on his bike to get in a hill ride before Dad & Tan arrived. The steepest section was for 3 km at 12% and he arrived back to camp absolutely starving. After I made a quick dinner, he promptly felt sick and curled up on the back seat for a while. I folded the laundry (our first wash & dry in a machine since they didn’t have laundry sinks at the campsite) and washed the dishes that had piled up for a few days since I hadn’t been feeling 100%. I then put Anoop’s dinner back in the fridge for later and tidied up around camp for heading off in the morning. The next morning he woke up feeling just fine and decided that perhaps he needed to eat at least a snack before heading off on a ride next time.

Gruyère production

Wednesday, September 05, 2012

Gruyères, Fribourg, Switzerland

Gruyères, Fribourg, Switzerland

Other Entries

-

11Grand vues from the Route des Crêtes

Aug 1917 days prior Ramonchamp, Francephoto_camera63videocam 1comment 7

Ramonchamp, Francephoto_camera63videocam 1comment 7 -

12Stork sighting at the écomusée

Aug 2016 days prior Ungersheim, Francephoto_camera43videocam 0comment 7

Ungersheim, Francephoto_camera43videocam 0comment 7 -

13Colmar

Aug 2115 days prior Colmar, Francephoto_camera48videocam 0comment 2

Colmar, Francephoto_camera48videocam 0comment 2 -

14Cute towns and Villages Fleuris

Aug 2214 days prior Eguisheim, Francephoto_camera30videocam 0comment 1

Eguisheim, Francephoto_camera30videocam 0comment 1 -

15Wine & Grape tasting in Riquewihr

Aug 2313 days prior Riquewihr, Francephoto_camera30videocam 0comment 2

Riquewihr, Francephoto_camera30videocam 0comment 2 -

16Haut Koenigsbourg

Aug 2412 days prior Chateau Du Haut Koenigsbourg, Francephoto_camera36videocam 0comment 7

Chateau Du Haut Koenigsbourg, Francephoto_camera36videocam 0comment 7 -

17Fountains and Lights in Strasbourg

Aug 2610 days prior Strasbourg, Francephoto_camera71videocam 2comment 3

Strasbourg, Francephoto_camera71videocam 2comment 3 -

18Clocks and Cakes

Aug 288 days prior Furtwangen, Germanyphoto_camera14videocam 0comment 4

Furtwangen, Germanyphoto_camera14videocam 0comment 4 -

19Off to Switzerland

Aug 288 days prior Schaffhausen, Switzerlandphoto_camera9videocam 0comment 1

Schaffhausen, Switzerlandphoto_camera9videocam 0comment 1 -

20Barfussweg

Aug 297 days prior Appenzell, Switzerlandphoto_camera29videocam 0comment 5

Appenzell, Switzerlandphoto_camera29videocam 0comment 5 -

21When the cows come marching in...Alpabfahrt!

Aug 306 days prior Appenzell, Switzerlandphoto_camera25videocam 1comment 5

Appenzell, Switzerlandphoto_camera25videocam 1comment 5 -

22A crash course in Appenzeller history and culture

Aug 315 days prior Appenzell, Switzerlandphoto_camera43videocam 5comment 1

Appenzell, Switzerlandphoto_camera43videocam 5comment 1 -

23Stamp Stop in Liechtenstein

Sep 014 days prior Vaduz, Liechtensteinphoto_camera22videocam 1comment 4

Vaduz, Liechtensteinphoto_camera22videocam 1comment 4 -

24Lucerne

Sep 023 days prior Lucerne, Switzerlandphoto_camera55videocam 0comment 3

Lucerne, Switzerlandphoto_camera55videocam 0comment 3 -

25Bears in Bern

Sep 032 days prior Bern, Switzerlandphoto_camera36videocam 0comment 0

Bern, Switzerlandphoto_camera36videocam 0comment 0 -

26Murten

Sep 041 day prior Murten, Switzerlandphoto_camera16videocam 0comment 1

Murten, Switzerlandphoto_camera16videocam 0comment 1 -

27Cailler Chocolate Factory

Sep 041 day prior Broc, Switzerlandphoto_camera30videocam 3comment 2

Broc, Switzerlandphoto_camera30videocam 3comment 2 -

28Gruyère production

Sep 05 Gruyères, Switzerlandphoto_camera54videocam 6comment 3

Gruyères, Switzerlandphoto_camera54videocam 6comment 3 -

29Château de Chillon

Sep 061 day later Montreux, Switzerlandphoto_camera29videocam 0comment 2

Montreux, Switzerlandphoto_camera29videocam 0comment 2 -

30A busy "rest day"

Sep 072 days later Aigueblanche, Francephoto_camera23videocam 1comment 4

Aigueblanche, Francephoto_camera23videocam 1comment 4 -

31Col de l'Iseran

Sep 094 days later Lanslebourg-Mont-Cenis, Francephoto_camera35videocam 0comment 2

Lanslebourg-Mont-Cenis, Francephoto_camera35videocam 0comment 2 -

32The toughest bike ride of my life

Sep 105 days later Saint Michel de Maurienne, Francephoto_camera40videocam 0comment 3

Saint Michel de Maurienne, Francephoto_camera40videocam 0comment 3 -

33Croix de Fer

Sep 116 days later Le Bourg-d'Oisans, Francephoto_camera23videocam 0comment 5

Le Bourg-d'Oisans, Francephoto_camera23videocam 0comment 5 -

34Alpe d'Huez

Sep 138 days later Alpe d'Huez, Francephoto_camera23videocam 0comment 3

Alpe d'Huez, Francephoto_camera23videocam 0comment 3 -

35Col du Lautaret

Sep 149 days later Col du Lautaret, Francephoto_camera37videocam 0comment 1

Col du Lautaret, Francephoto_camera37videocam 0comment 1 -

36Col d'Izoard

Sep 1510 days later Briançon, Francephoto_camera37videocam 0comment 6

Briançon, Francephoto_camera37videocam 0comment 6 -

37Briançon

Sep 1611 days later Briançon, Francephoto_camera30videocam 0comment 3

Briançon, Francephoto_camera30videocam 0comment 3 -

38Mont Ventoux

Sep 1813 days later Malaucene, Francephoto_camera47videocam 0comment 1

Malaucene, Francephoto_camera47videocam 0comment 1 -

39Escargots & Grenouilles

Sep 1914 days later Pont en Royans, Francephoto_camera44videocam 0comment 4

Pont en Royans, Francephoto_camera44videocam 0comment 4 -

40Choranche Caves

Sep 2015 days later Pont en Royans, Francephoto_camera30videocam 0comment 3

Pont en Royans, Francephoto_camera30videocam 0comment 3 -

41Cinque Terre

Sep 2217 days later Levanto, Italyphoto_camera55videocam 0comment 2

Levanto, Italyphoto_camera55videocam 0comment 2 -

42Venice

Sep 2520 days later Venice, Italyphoto_camera96videocam 0comment 6

Venice, Italyphoto_camera96videocam 0comment 6 -

43Forni di Sopra, a quick visit

Sep 2621 days later Forni di Sopra, Italyphoto_camera16videocam 0comment 0

Forni di Sopra, Italyphoto_camera16videocam 0comment 0 -

44Davos

Sep 3025 days later Davos, Switzerlandphoto_camera46videocam 1comment 1

Davos, Switzerlandphoto_camera46videocam 1comment 1 -

45Schilthorn and North face walk

Oct 0227 days later Lauterbrunnen, Switzerlandphoto_camera56videocam 3comment 5

Lauterbrunnen, Switzerlandphoto_camera56videocam 3comment 5 -

46To the "Top of Europe"

Oct 0328 days later Lauterbrunnen, Switzerlandphoto_camera76videocam 5comment 7

Lauterbrunnen, Switzerlandphoto_camera76videocam 5comment 7

Comments

2025-05-22

Comment code: Ask author if the code is blank

Gruyères, Fribourg, Switzerland

Gruyères, Fribourg, Switzerland

Mike J

2012-10-16

Cool! Is the cheese maker actually pulling on the cheesecloth with his teeth?

Interesting, the process looks very similar to an old style chinese tofu factory - same sort of bins, use of straining cloths, presses and cutters ... :-)

Cheers,

Mike