The holidays are over, and it’s now time to begin the

dreaded bodywork and paint. It’s been

almost 50 years since I’ve done any bodywork (on a 1963 VW bus), and I’ve never

picked up an auto spray gun in my life.

How hard can it be? Yeah,

right! When the cab was originally media

blasted, it was primed with epoxy primer from Southern Polyurethane. I didn’t really want to mix paint brands, and

since I don’t know which brand I will be using for final paint, it made sense

to me to just stick with Southern Polyurethane.

So I ordered a fresh gallon of epoxy gray primer and activator, a gallon

of regular 2K primer and activator, and a gallon of single stage gloss black

and activator.

Southern Polyurethane recommends using filler on top of

their epoxy primer, and the fillers recommend using filler on bare metal. No controversy there! For filler, I decided to go with Evercoat

Rage. It’s a little more expensive, but

it supposed to go on smoother and be easier to sand. I also bought a small can of Evercoat Fiberglass

stranded filler as it is stronger and waterproof.

I plan to use the Evercoat Fiberglass around

the windshield and cowl vent where I don’t want any water leaks. The Evercoat Rage will just be used as a skim

coat where I have either butt welded patch panels, or there is some significant

scaling from the remnants of rust after media blast. All rust through spots or panel thinness have

either had the panel replaced or the pinholes have been welded shut. There are no pinholes to be filled with filler!

Before starting the filler, there is area of metalwork that

I decided to fix. At the lower corners

of the firewall where it meets the inner fender, there are a couple of panels

that are attached with sheet metal screws.

It looks like an afterthought, so I decided to make my own in the same

shape, but to weld them in place. They

came out pretty good, and I can always shape the edge if I need a better fit.

So I began the filler at the firewall. Using various sanding blocks and 80 grit

sandpaper, I was able to smooth over the areas where I had welded over a series

of holes.

There was also a small dent

where evidently the engine had come in contact with the firewall during

disassembly, which I managed to pound out as best as I could and fill the

imperfections. Next I moved to the

interior, mostly around the rear cab braces where I had plug welded in new

ones, and around the new upper windshield brace. These don’t need to be perfect, as they will

be mostly covered by trim, but I wanted to get rid of most of the glaring

defects. Same for the kick panels, they

are already mostly straight, but needed a little cleanup where they had been

welded in place.

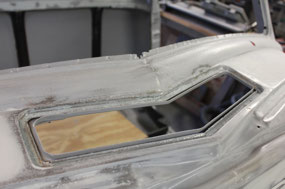

Next I moved to the cowl vent area. There were originally a few pinholes, but the

metal was still pretty thick. All the

pinholes had been welded shut and the metal ground smooth. I used the Evercoat Fiberglass for the final

smoothing, especially around the rubber gasket surface to try and minimize

water leaks. Next I moved on to the roof

and cab corners. These were already

pretty straight, so it was mostly just skim coat and block sanding for final

smoothness.

The last major area to attack was the rear of the cab. Most of the cab rear will be covered by the

bed when it is installed, but there was significant damage to the rear of the

cab from stuff bouncing around the bed over the years. I did the best I could with a hammer and

dolly to straighten most of the ripples.

The inside is behind the seat and will not be visible. I took my time and also made sure there was

no “oil canning” of the sheet metal where a dent could pop in and out. My 12” sanding block just wasn’t long enough

so I bought a 28” flexible sanding block that worked great! I took my time, and it came out pretty

straight, and I don’t think there is any filler over 1/8” thick, mostly much

thinner.

After filling around the cowl near the outside mirror

locations, I noticed there was filler around the mirror attachment bolts, and

that there was a gap between the body and the inner brace where the mirror

attached. I had a concern that when I

tightened the mirrors, it might crack the filler near the bolt holes, so I

opened up the holes, welded in a spacer on both sides, and ground everything

smooth.

Now when the mirrors are

tightened, everything will tighten against metal.

Now that the bodywork on the cab was about done, it was time

to flip the cab onto the firewall, and take a look at the underside. There were a few pinholes around the

driveshaft relief I had welded in place which I closed up with some additional

weld, and a little grinding and finishing on welds that I had done from

above. While the cab was sitting on the

firewall, I was able to finish the block sanding on the roof.

Now that the bodywork is done on the cab, it was time to verify

the paint strategy. In a perfect world,

I would build this truck like they do on the TV shows, and I would complete all

the bodywork and paint on the cab, trial fit everything, disassemble, and do

the final paint. It looks so easy on

television! But this is how it’s going

to go. I’m going to prime the underside

of the cab, the shoot a couple of coats of gloss black. Then spray the flat surfaces of the underside

with paintable rubberized undercoat, and a final coat of gloss black.

The underside is now done. Then I will flip the cab back upright, mask

off the underside, and finish the priming on the interior and top side of the

cab. Then I will mask off and paint the

firewall and the interior floor, behind the seat, the kickplates and behind the

dash with gloss black. At this point, I

have still not welded the dash in place.

This is because I wanted everything behind the dash epoxy primed and

painted to prevent rust. Once the cab is

fully primed and painted behind the dash, I will prime the dash, prime and

paint the backside of the dash, and weld it in place. Then I will finish the metalwork around the

windshield, touch up the primer around the windshield, and be ready to final

attach the cab to the frame. Since the

underside, firewall and interior floor and behind the dash are painted black, I

will be able to install the wiring harness, all the electronics, and the

heater-A/C and get everything drivable in primer. I may even install the glass without sealant

to make sure it all fits and still be easy enough to remove for paint.

Once it is drivable in primer and mostly

complete, then I can take it somewhere for paint, and either they or I can do

whatever disassembly is necessary for paint.

It may not be a perfect plan, but that’s what I’m thinking.

The first step for painting is to build a paint booth. As an engineer, I, of course, tried to

overthink it. In the end, I just screwed

some 1x2 strapping into the ceiling and stapled plastic sheeting to the

strapping giving me a apace about half the size of the garage covered on four

sides with plastic. Then I would prop

open the garage door by a couple of feet and run a room fan blowing air out of

the space. Not great, but good enough

for primer. Southern Polyurethane has

some pretty good instructions for preparation and paint that came in a booklet

with the paint when it was delivered. I

used a Harbor Freight HVLP gun, and gave it a shot. Painting is HARD! But it is fun! Priming on the underside came out pretty good

on the first try, but the gloss black was a lot tougher.

I was getting some orange peel, and thought I

had read that the problem was either pressure too high or not enough paint

flow. So I reduced the pressure and

increased the flow and it just made it much worse! I went back to the instructions and read a

little closer, and realized that I had done exactly the wrong thing! So I increased the gun pressure and returned

the flow to normal and it came out much better.

Between the priming and the gloss black, I also had to go

over every seam with seam sealer. For

the intearior and underside, I just used the AC-Delco single part seam sealer

in a caulk gun tube. I did use painters

tape to mask off a straight line on either side of the seam, and removed the

tape while the seam sealer was still wet.

It all came out great! The rest

of the cab priming and painting was without incident, and I was getting a

little better with each try. Once the

cab was done, I primed and painted the dash, dash brace, tunnel, and battery

box cover which came out great. Welding

the dash in place was fairly easy, except that once I had it all welded in

place and was admiring my work, I looked up and realized that I had not

installed the dash brace in place before welding.

In the

past, I had always installed the brace before setting the dash in place, and I

wasn’t sure it would fit with the dash already installed. It took me a while, and a little panic, when

I finally found the spot where the brace would drop into place. Whew! Dodged a bullet there! After the dash, I welded up all around the

windshield, and made sure that it was all metal without holes all around the

opening. At this point I was finally

able to install the split windshield brace that I had been waiting so long to

install. Then I ground everything smooth

as I could and filled the imperfections with the waterproof Evercoat Fiberglass

filler. There was also a spot above the

passenger’s windshield where the previous owner had replaced the metal and the

bend wasn’t exactly right. I was able to

make up the imperfection with the Evercoat Fiberglass so that now the entire

windshield opening looks great.

The other thing I noticed was a gap between the rain gutters

and the body. I was originally just

going to use the same seam sealer as I used everywhere else on the rain

gutters, but decided it would probably be better to use the 2-part epoxy seam

sealer in this location.

I also had to

replace my caulking gun with a much stronger one, and I had read warnings that

it would be too difficult to press the trigger on a standard caulk gun since

this tube had both epoxy parts in the same tube and it mixed along the way as

it came out. Luckily I found a 26x gun

on Amazon.

It was a little tricky

to mask everything off to only expose the inside and outside of the windshield

opening and the dash attachment points, but once masked, it was easy enough to

do the final primer touchup. At this

point, painting is done for a while, and I was able to roll up the plastic

sheeting while still stapled to the ceiling and tie strap it up and out of the

way. When I next need to paint, I should

be able to quickly roll down the plastic sheeting and recreate my spray

booth.

One thing that became apparent during this priming and

painting exercise is that there is just no way would I be successful at doing

final paint in the garage. It is just

too difficult, and there are too many variables to have it come out well. It takes talent, practice and equipment and a

much better facility than I have. So for

now, I will limit myself to priming, and painting brackets, inner fenders, and

the like, and when I am ready for final paint, I will leave it to the

professionals.

Orlando, Florida, United States

Orlando, Florida, United States

2025-05-22