Up to this point, while it may appear that everything has

gone perfectly, it has not. It is now

time to go back and fix the mistakes that I know about. I’m sure I’ll uncover more, but for now, I

want to fix the things that will allow me to drive it around the neighborhood

more or less safely. First step is to

replace the defective master cylinder.

This should have been a simple replacement, just 2 nuts and 2 brake line

fittings. This time, I painted the new

master cylinder, and a couple of days later, placed it in the vice surrounded

by a couple of rags and followed the bench bleed procedure on the bench this

time. It’s actually much easier on the

bench than doing the bench bleed in the truck.

After bleeding the master cylinder, I installed it in the

truck and tried pumping up the brakes – no luck. I guess there’s just more air than I thought. I was going to have Jody help me bleed the

brakes, but since she’s not home, I decided to try the vacuum bleeder one more

time. This time I used it correctly, I

left the bleeder closed, attached the vacuum bleeder and pumped it up.

Then I cracked open the bleeder until it bled

off, then closed the bleeder again. I

repeated this procedure until bubble-free brake fluid came out, and then

repeated it on all 4 wheels. Everything

looked great, there wasn’t very much air in the lines, but when I tried the

pedal again, and it went straight to the floor.

No amount of pumping would bring up the pedal.

I went back and looked at the old master cylinder, when I

realized that the cutout for the plunger in the old master cylinder was much

shallower than the new one. A closer

inspection showed that there was a metal cylinder inserted into the plunger to

take up most of the depth. I popped it

out and realized that since the power brake booster had a short shaft, I needed

to install this cylinder into the new master cylinder. So I took it back apart, installed the metal cylinder

in the new master cylinder and rechecked the brake pedal. This time it worked perfectly! Checked for leaks, and it all looks

good! So I started it up, put it in gear

and tested the brakes.

They worked

perfectly!

I drove the truck back down the driveway so I could wash off

any residual brake fluid that had dripped on the frame or body. It all looks good now. As I moved the truck, there were a few

rubbing noises as it moved. The first

was the front tires rubbing on the fenders.

This I already knew about, and is my fault for measuring for the wheel

offset without weight on the front suspension.

When fully loaded, the front wheel track width was close to 72” and

should have been more like 69” to 70”. I

could jack up the front suspension and probably get some clearance, but the

right way to fix this is to replace the front Foose wheels with 34mm offset

wheels like the rear instead of the 1 mm offset that I have. This will move each wheel inward by 33mm or

about 1.25 inches. This should make the

track with about 69.5 inches which should be perfect. I ordered the replacement wheels from Summit

on 7/7, but it might take a few weeks to get them drop-shipped. Unfortunately, the reason for the 1mm wheel

selection in the first place was to have clearance for the front sway bar.

Now I will need to redesign the sway bar after

the new wheels are installed.

When listening for noises, I also noticed an additional

noise under the cab that sounded like drive shaft rubbing. Sure enough, I looked underneath and the

front u-joint area of the drive shaft was just rubbing on the floor of the

cab. A closer inspection showed that the

since the bottom of the seat is removable, there is a recessed area under the

seat for storage. This area drops a

couple of inches below the cab floor and interferes with the drive shaft. I decide that for now, I would just cut a 4”

wide strip in the floor above the drive shaft. Clearance looks good, but I’ll

need to clean up the opening and add some metal strips to close the opening

when the cab comes off next time.

The MAF extension cable I ordered from eBay came in, and

while the pinout is correct, the keying is not quite right. The male pin end will work, but the female

pin end will not. I ordered a pigtail

connector from Amazon, and spliced it in place.

The cable now works great, and the truck starts every time.

I was hoping to get the new front wheels to check the

updated clearance, but the ship date is Aug 24 and I’m tired of waiting. So I decided it was time to get the cab and

doors media blasted. Unfortunately, over

the weekend, I was stung on the ankle by a hornet, and my leg and foot are

swollen. So I was only able to search

for a media blast place on the internet while I was recovering. In the end, I picked Blast Off Orlando (www.blastofforlando.com) they seemed

to have the equipment I was looking for, and had a background doing mostly cars

and restorations, and a lot of Corvettes.

So I drove down to West Grant St, near downtown Orlando to check the

place out. It was exactly what I was

looking for! Basically it’s a 1-man

operation, with a couple of helpers.

There were several cars around in various stages of restoration. Hanging on the wall were a couple of doors

and bed sides for a truck like mine. I

spoke to Art, told him what I had, and he said he had done many cabs like mine

as they are very popular.

I asked about

pricing, and it was $450 for the cab, $125 each for the doors for a total of

$700. If I wanted them primed, it was

50% more or $350, or $1000 total. He

said to bring it in whenever I was ready, and it would be done within a week.

Sounded good to me, and I asked him about primer, and he said

he always uses Southern Polyurethane Epoxy Gray Primer. This is a non-porous primer, so it both

primes and seals the metal. Most regular

primers are porous, and over time it will begin to rust through the

primer. He said he’s seen this primer 10

years later still with no rust. It

sounded good to me, so I will order some for my own use to finish priming after

I’ve finished the metalwork. By

Wednesday, the swelling on my foot was back to normal, so I disassembled the

doors from the cab, and the cab from the chassis. On Thursday morning, I rented a U-Haul

trailer, loaded it up and headed over.

By Thursday afternoon, my baby was gone, hopefully to look much better

when it came back.

The following Wednesday morning, I got a text telling me my

truck was ready. I stopped at U-Haul,

got the trailer again and headed over to pick it up. It looked great! He did an excellent job getting into all the

nooks and crannies with both the media blast and the primer. The primer actually has a slight gloss, and

it looks like it should hold up well. At

first glance, the cab looked good for pinhole rust, but I’ll do a closer

inspection when I get home. So we loaded

up the trailer and headed home. Of

course, being Florida, it rained all the way home making me especially glad

that I had it epoxy primered before I took it home.

I did a close inspection of the metal and it’s almost all

good. There are a few minor pinholes

around the cowl vent, but I should be able to drill them out and weld them

shut. There are also a few small

pinholes at the back near the floor that I should also be able to weld

shut. The drivers cab corner had been

replaced, but the passengers cab corner didn’t look too bad.

After media blast, the passengers cab corner

will need to be replaced. Fortunately,

Matt included the replacement cab corner, so I will just need to weld it

in. Matt had also replaced the lower

inner and outer skin of the passenger’s door.

It looks great, but the driver’s door will need these pieces replaced

also. I don’t have the parts, but

they’re no expensive. Hopefully I can do

as good of a job as Matt!

We’re getting ready for our trip to Hawaii, so I’m not ready

to tackle the metalwork until we return.

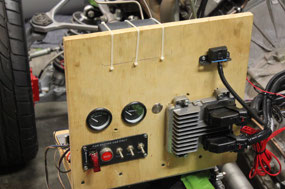

But now that the cab is off, I figured it was time to tackle the parking brake. I didn’t really want to use the factory

parking brake pedal as it’s huge and comes through the floor. So I looked at aftermarket under dash pedals

and handles, but by the time I bought all the parts and the intermediate

cables, it was looking pretty pricey.

What I did find was a YouTube video about an eStopp electronic parking

brake that was essentially a linear motor and controller that essentially a

push button parking brake like on Jody’s Subaru.

Press the button and the motor pulls the

parking brake cables and shuts off at 600 lbs.

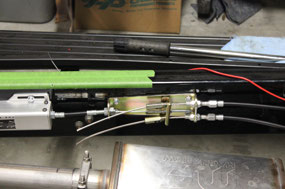

Press it again and the motor releases the parking brake cables. The unit is only about 18”x3” and should

mount easily on the inner frame rail.

They also have a nice bracket to mount the cables and pull bracket

making a really professional installation.

The biggest problem is that it costs $479, but when I did the math for

pedals, cables, etc. it’s actually a little cheaper. Also, Summit was having a $50 off coupon, so

I was able to get it for “only” $429.

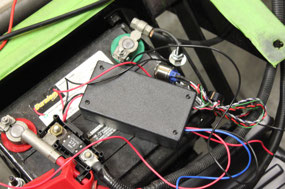

I mounted both the eStopp and the bracket to the inside

passengers frame rail, drilled a couple of 7/8” holes through the frame for

parking brake cable routing, and added a couple of 3/8” clamps to hold the

cables in place. After hooking it all

up, adjusting the cable length, and mounting the button to the control panel, I

pressed the button and it all worked perfectly!

It’s very impressive and so much easier than designing a complicated

system.

For now, I think we are at a break point. We leave next week for a trip to Hawaii, and

I hope to start the metalwork when I get back, I test fit the kick panels and

the braces, and it all looks promising. I’ll

just need to practice my plug welding, so that everything comes out looking

professional. Meanwhile, Hawaii is

calling!

Orlando, Florida, United States

Orlando, Florida, United States

2025-05-22