The time has come for the moment of truth. This is really more a test of whether Darryl

did a good job of laying out a bare frame that would actually fit. So far, everything has looked good, though

the engine appeared to be a little forward in the engine compartment, which I

remedied by using different motor mounts.

The question is whether I moved it too far back that it may interfere

with the firewall. My measurements looked

good, but now is the time to find out for sure.

One thing for certain is that the late model 6L80E

transmission is much larger than the original 3-speed, and protrudes into the

cab. This is completely expected, and as

the original floor was basically flat, I will need to cut out some floor and

toe plate to make room for the transmission.

I will then need to construct a transmission tunnel to cover over the

hole. The original floor already has a

removable plate, and it looks like the transmission will fit in that

opening. The toe plate is another

story. It will definitely need to be

cut, but since it is at an angle, and the transmission rises at a different

angle, it is difficult to make this cut from measurements.

I also need to keep this cut as small as

possible on the driver’s side, as I don’t want the tunnel to interfere with the

gas pedal location.

I good metal fabricator would probably just make some

initial measurements, remove some of the metal, and finish the cut while the

cab was suspended In the air as it was being lowered on the frame. Since I am not a good metal fabricator, and

since my background is engineering, I resorted to what I would have done back

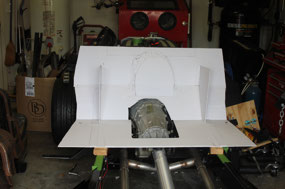

at Lockheed as an engineer – build a foam core mockup! It’s surprising how close you can get with

some foam core board, a single edge razor blade, and a hot glue gun. So I spent a relaxing afternoon with my arts

and crafts project of laying foam core onto the cab floor and gluing it all

together with hot glue. I used the front

body mount bolts as a locator.

After completing the mockup, I cleared all the wiring

harness out of the way on the chassis – I had to disconnect parts of my wooden

control panel to get it out of the way.

I used wooden blocks to set the height above the frame and lined up the

mockup using the front body mount bolts.

As I set it in place, I trimmed portions of the toe plate with a razor

blade until it all set down flat. It

fit! Engine/ firewall clearance is

good. I took the time to mockup the

firewall engine relief to be sure the intake and wiring would clear, and it

looks great also. I had also marked the

mockup with steering column location and master cylinder location and they both

looked great too.

On the driver’s side, the cutout went right through the cab

floor mount gas pedal location, so I went ahead and cut the gas pedal brackets

off the cab floor so I could fill in the foam core and make a better

mockup. Finally, the mockup was

perfect. I removed it from the chassis

and put it back in the cab so I could mark the toe plate cutout with a

Sharpie. The piece to be cut out was 11”

wide and 7” tall. There was no turning

back now – so out came the die grinder which made quick work of the toe

plate. It looked good.

It was now time to try out my new overhead electric

hoist. So I built a spreader bar out of

2x4’s and used the same nylon strap to hook up to the cab and lift it off the

dolly.

So much easier with the electric

hoist! With the cab lifted in the air, I

put my 4 wheel dollies that Jody got me for Christmas under the chassis and

spun the chassis around in the garage until it lined up under the cab. The front bolts dropped right in, and the

rear shackles also lined right up after a little jiggling with the hoist.

The cab was installed!

Bolted in place, and all clearances were good. The mockup had been pretty accurate. Clearances were even slightly better than the

mockup. I had been able to keep the

entire gas pedal floor mount area intact around the transmission, so gas pedal

fit should not be a problem. So I spun

the truck around one more time in the garage with the engine pointing outward

so I can continue test fitting some of the sheet metal. I’ll need to cut the inner fenders around the

corvette A-arms so I can see how the front fenders fit around the tires. I have a universal transmission tunnel on

order as a starting point for transmission tunnel fabrication. There’s plenty of work to keep me busy for a

few more weeks before I have to take the cab back off for media blast. But for now, it’s time to admire my

handiwork, and clean the garage!

Orlando, Florida, United States

Orlando, Florida, United States

2025-05-22