At some point, it occurred to me that the radiator core

support was not perpendicular to the frame.

From what I could tell from pictures, the core support does pitch

forward, but the angled mount on the radiator causes the face of the radiator to

be perpendicular to the frame. So I put

a level on the frame and jacked up the rear of the chassis so that the frame

rails were level. This allowed me to

place a level on the radiator face, and add shims under the core support to

make the radiator vertically level and therefore perpendicular to the

frame. Of course, when I did this, I

lost a little of the space between the waterpump and the radiator and the fan

no longer fit.

So now it was back to the drawing board on the fan. I had always been concerned with the 16” Spal

fan, that it only had 1500 cfm and various articles had called for something

more like 2500 cfm. Since I did not have

room for a puller fan, it was time to look for a pusher fan that I could locate

in front of the radiator.

Most of the articles

recommended Derale Fans as a more robust version and I found just what I wanted

at Summit Racing. The Derale 16917 is a

17” 1800/2500 cfm dual speed fan that is only 2.65” thick and is designed to be

mounted either in front of the radiator as a pusher or behind the radiator as a

puller. Sounds perfect! So while I was waiting for the fan to come

in, I decided to tackle the radiator hose routing.

The upper hose was fairly straightforward, and I bought some

2” pool vacuum flex hose that I could use to mock up the path. The upper went fine, and the flex hose could

easily be bent to follow the path. The

lower hose was a problem. The lower

radiator outlet points directly at the A/C compressor clutch and needs a quick

90 degree turn. I bought a lower hose

with a 90 degree bend so I could cut off the 90 degree and transition from the

90 degree hose to the pool vacuum flex hose.

It sort of worked, but the 90 degree elbow was very close to the A/C

clutch. I decided to take the radiator

to a local radiator shop and see if they could install a 90 degree elbow.

They sent it out to their fabricator, and figured

out that it would be just too difficult and expensive to modify the radiator,

and that I should try some other solution.

I thought about sending the radiator back to the manufacturer for

modification, or ordering a new, modified radiator, but I suddenly realized

that if I just moved the entire radiator mounting to the core support down

about an inch, my clearance problem would be resolved!

So I cut a notch into the base of the core support, and

drilled new mounting holes in the radiator angle mount and I was able to run

the lower hose 90 degree bend with plenty of room to spare. The 1 inch drop at the upper tank is barely

noticeable and should look fine when all the sheet metal is attached. I did have some concerns about structural

integrity of the core support as the notch cut in the support to lower the

radiator did compromise some of the strength.

But the next step was to install the Derale fan and I decided to use a

pair of 1”x1”steel angle irons as a mounting bracket.

By the time I bolted the two 1”x1” angle

Irons to the core support to mount the fan, all structural integrity had been

restored.

The fan mounting brackets came out great, and I had to use a

technique where I cut and folded over an end of the angle iron and welded it

together so I could install a bolt from the end. It’s all really strong and professional

looking, with the fan mounted to the angle iron with rubber insulators and I drilled

and filed the mounting holes square so I could use carriage bolts. It all looks great, and I should have plenty

of room to mount the A/C condenser in front of the radiator with the fan

sandwiched in between. Since this is a

2-speed fan, and the ECM is programmed for 2 fans, the plan is to hook the 1800

cfm wire to Fan-1 and the 2500 cfm wire to Fan-2. This will take 2 relays, but it should make

for a reliable and quiet installation.

The radiator and core support were then disassembled and

everything was primed and painted gloss black to match the rest of the chassis,

and then reassembled for final installation.

It all looks great! After looking

to see if I could find anything that looked worthwhile in a preformed radiator

hose, I decided I would use stainless flex hose with rubber couplings on the

end. The upper radiator hose would use a

chrome cover over the rubber coupling for appearance, but the others were not

readily visible, so an exposed rubber coupler would be fine. The

stainless flex hose is 1-5/8” OD, with the couplers set for 1-3/4”. There are rubber reducers to step down to

1-1/2” or 1-1/4”, so the upper hose used the 1-1/2” step down at the radiator

inlet and the 1-1/4” step down at the waterpump. The lower hose also used a 1-1/2” step down

at the water pump, and after several tries for the 90 degree coupler at the

lower radiator outlet, I settled on the 90 degree coupler designed for the

stainless flex, with the chrome cover removed for clearance. All in all it looks great! I also installed the heater hoses, making

them about 4’ long with a loopback coupler at the end so they should be ready

to remove the coupler and cut to length when the cab is installed.

I had originally connected a loopback hose across the

transmission lines to start the engine, but now that the radiator was

installed, I might as well connect the transmission lines to the radiator. I had some leftover steel line from the

factory fuel lines that came with the engine, and I was able to cut out some

pieces with the appropriate bends to connect between the cut off transmission

lines and the bottom of the radiator. A

couple of adapters and some quick work with the flaring tool, and the lines

dropped into place. Rather than get too

fancy with the coupling between the new lines and the existing transmission

lines, I just used brass compression fittings which worked just fine.

I was almost ready to fill all the fluids, when started

thinking about how to fire up the engine.

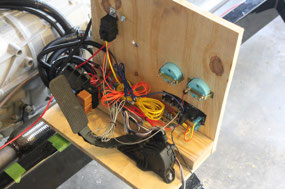

I decided I would just build a plywood panel to mount the computer,

switches, terminal boards, gas pedal and relays. For safety, it also made sense to install an

oil pressure and water temperature gauge.

I used electric gauges as that would also be used in the final assembly,

and wanted to set up the sending unit locations. I ordered a couple of cheap gauges from

Amazon, and figured out what adapters I would need for the sending units. Oil pressure was easy, as I already had a

1/8” NPT hole at the oil cooler blockoff plate above the oil filter. I did need to add a 90 degree adapter to tuck

the sending unit away from the exhaust.

On the rear of the passenger side head, is a 1.5 mm threaded plug that

leads into the water jacket. I just

removed the plug, added a 1.5mm to 1/8” NPT adapter and the water temperature

sensor dropped right in.

Now that all the fluid reservoirs were complete it was time

to add oil, coolant, power steering fluid, and transmission fluid. All the fluids were added and no leaks! The next step was to lay in the wiring harness

and build the plywood mounting plate. I

was able to locate the mounting plate on the driver’s side body mount and all

the wires would reach.

The PSI

Conversions wiring harness dropped right in and all the lengths and connectors

were perfect. I mounted the battery tray

to the frame and was able to reuse the battery cables that came with the

engine. I did have to run a new 4 AWG

wire from the alternator to the battery cable positive terminal. Of course, crimping lugs on 4 AWG wire meant

I had to buy a hydraulic crimper which made quick work of the crimp job. I set up 2 terminal boards, one for +12 VDC

battery power and one for switched +12 VDC.

I also had to run a wire for the start button to the starter solenoid

which for some reason was not included in the harness. I wired up the gauges, and even added a Check

Engine Light to the panel. I wired up

two fan relays and added a connector at the fan pigtail to facilitate maintenance. Of course, I also had to run a fuel pump wire

back to the fuel tank, but this was only temporary, as the real fuel pump wire

will need to be part of the chassis harness.

The wiring all looked pretty good, and it was time to look

for a battery.

Since I was using the

stock frame mount battery box, which was designed for a 6-Volt battery, I was

somewhat limited in battery size to the confines of the battery tray. This meant I needed a 9” x 7" x 8” tall battery. I

also wanted the positive terminal on the left so my battery cable configuration

would work out. Turns out, this is a

Size 85 battery, and while I was originally going to use an expensive Optima

battery, the dimensions seemed a little off, so I ended up with an AutoZone

Duralast Gold 5-year battery which should work just fine.

After hooking up the battery without incident, we were

getting close to the moment of truth. I

put a couple of gallons of fuel into the tank, connected a fuel pressure test

gauge to the fuel rail and hotwired the fuel pump. The fuel pressure read about 60 psi which is

perfect. I connected the OBD diagnostic

to the port and tried to establish communication to either my phone or to my

laptop with no luck. I connected to the

Silverado and it worked fine, so it had to be something with the ECM.

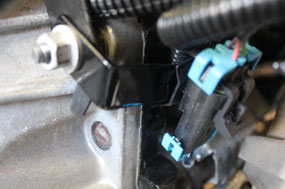

Then I remembered all the warnings about the

transmission connector on the 6L80E. The

PSI Conversion website even had a video showing how to be sure the connector

was mated correctly. Knowing all this, I

had paid close attention to the transmission connector hookup, and was sure I

had done it correctly. Of course I

hadn’t. And when I disconnected it and

looked closer, I realized it was not fully seated just as they had warned. I reseated the connector correctly this time

and the communication problem with the OBD was resolved!

It was now the moment of truth. I flipped the switch to ON and pressed the

START button and the engine fired right up and ran! Oil pressure and the OBD looked good, but I

had to shut it down quickly as the driveshaft was not yet installed and

transmission fluid began pouring out of the tailshaft. Luckily the driveshaft from Denny’s

Driveshaft was due later that same day, and when it came in it fit

perfectly! When I fired it back up, it

all looked great with no leaks anywhere.

I let the engine warm up, hoping to check out the fan relay and see if

the fan would keep the engine cool.

Unfortunately, as soon as the thermostat opened at 190 degrees, the

upper radiator hose blew off the waterpump.

Thinking I had forgot to tighten a clamp, I reconnected the hose, made

sure everything was tight, refilled the coolant and tried again with the same

results. It turned out the reducer that

took the 1-3/4” coupler to a 1-1/4” coupler did not have enough friction. I decided I just didn’t like the design and

ordered a 1-1/2” to 1-1/4” coupler and was able to squeeze the 1-5/8” hose into

the 1-1/2” end and the 1-1/4” end to the waterpump. I tightened everything back up, refilled the

coolant, and tried again. This time

everything worked perfectly and the temperature rose to 190 degrees, opened the

thermostat and the fan came on at 195.

When the fan came on at 195, it cooled the engine to 192 where the fan

went back off again. It all worked

great! Of course, it wasn’t hot enough

to switch on the high speed relay, but I’m sure it will be plenty warm in the

summer to test the Fan-2 relay.

Everything was looking good, when the check engine light came

on. The OBD showed it was a PO-174 code

(Bank2 Lean). Eventually it would also

show a PO-171 (Bank1 Lean) code also. Of

course, this sent me to the internet I search of a solution. It turns out this code or pair of codes is

normally associated with a manifold vacuum leak which is evidently fairly

common with the Chevy 5.3 plastic intake manifold. Before I got too panicked, there were several

suggestions to look for a vacuum leak including the “propane test” where you

point an unlit propane gas bottle at the intake joints while watching short

term fuel correction to look for a jump.

Or building an intake smoke detector, where you use low pressure

compressed air and a paint can to inject smoke into a sealed intake and look

for smoke escaping. I tried both methods

and found no evidence of a leak.

I also found that the Chevy 5.3 does not have a

PCV valve, it just has a PCV orifice which is a calibrated vacuum leak orifice between the inlet air by the

MAF Sensor and the orifice in the driver’s side valve cover.

The driver’s side valve cover was not

blocked, but I had moved the inlet side intake to the base of the air filter

before the MAF Sensor instead of between the MAF Sensor and the throttle body

as was the original design. I did this

because the aftermarket cold air inlet was too long and I needed to shorten it

up. I looked at design recommendations

for cold air inlets and decided buy a coupling and add the section of cold air

inlet that contained the PCV port back in between the MAF Sensor and the

throttle body. I hooked everything back

up and the check engine light did not come back on! I checked both the short term and long term

fuel correction and both were hovering around 0 +/- 5 which is excellent.

The last test was to jack up the rear wheels and try the

transmission in both forward and reverse.

Both forward and reverse worked perfectly and it should be ready when I

have a steering column and brakes! I

also wanted to test out the steering rack, so I bought the u-joint down at the

rack and a length of steering shaft.

That’s when I found out I have a clearance problem between the u-joint

and the driver’s side motor mount. It

almost fits, but it looks like I will need to trim some of the metal away from

the mount. The mount is a 4-sided piece

of steel that Darryl at Rockabilly put together. I will need to clearance some of it at the

bottom, but I believe it is way overdesigned and the removal of some of the

metal should not have an adverse effect.

At this time, I’m not sure just how much metal and where it needs to be

removed and I won’t know for sure until I have a steering column installed in

the cab. So for now, I was able to

rotate the shaft and prove the power steering rack works correctly, and I will

leave the motor mount modification until after the steering column is

installed.

At this point, the chassis is generally complete. I start the engine about once a week to make

sure it still starts, and sometimes let it warm up to operating

temperature. For Christmas, I got a set

of wheel dollies so I can now move the chassis around the garage easily. After January 1, I will begin the search in

earnest for a body so I can begin the next stage of assembly. I can hardly wait!

Orlando, Florida, United States

Orlando, Florida, United States

2025-05-22